Contributed by Bob Kozickie, Technical Sales Support Manager

Master Links and Master-Sub Assemblies are the first components to consider when assembling an alloy chain sling because they serve a very critical function. They are the strongest single component under the crane hook that is required to support, not only the chain sling itself, but the entire load being lifted below it. If not sized or selected correctly to work safely in conjunction with the crane hook, it could potentially lead to a catastrophic failure.

There are three important factors to take into consideration when choosing the proper master link to fit each application: the number of sling legs, the size of the crane hook, and the crane hook’s design to which the sling is required to be placed while lifting the load.

Number of Sling Legs

Single leg alloy chain slings are designed to lift loads having a single lifting point and have the chain sling tag rating stamped at a ninety degree angle to the load. This is the only angle which it is capable of lifting using a single attachment location. The slings’ capacity rating will ultimately be determined by the grade of the weakest component used in a straight line pull.

The same master links that are used to accommodate the single leg alloy chain sling can be used for double leg slings as well. They will be required to meet the minimum capacity of the sixty degree angle for the grade of alloy components used to comprise the sling. Master links used in this configuration are required to be proof tested to 4 times the rating of a single leg sling. Multiple leg slings must to be rated at either 60, 45, or 30 degree angles on the tag. This is due to the fact that for any two given lifting points, the distance between the lifting points will always be at an angle less than ninety. When this occurs, it is assumed that the angle is 60 degrees. Refer to post, How to Read and Understand an Alloy Chain Sling Capacity Chart for additional important tips.

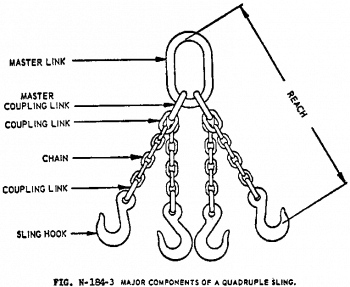

Three and four leg alloy chain slings are required to be assembled onto a Master-Sub Link Assembly. This is stated in both OSHA 1910.184 and ASME B30.9. The OSHA FIG. N-184.3 drawing of a quad alloy chain assembly clearly shows a master link with welded sub coupling links. The main master link must to be proof tested to six times the rating of a single leg sling in order to be compliant for use on a triple or quad alloy chain sling. The sub joiner links will then hold one or two sling legs depending on if it is a three or four leg chain sling. The larger master-sub coupling links are recommended to be used to assemble slings with adjuster legs. Mechanical Coupling Links as sub joiner links is not permitted. Placing a single chain leg and shortening leg onto the same mechanical coupling link is also not permitted. Mechanical coupling links are designed for use in a straight line pull and there is no prevision to have a 120 degree included angle on the mechanical coupling link which is a requirement on a welded master sub link.

Three and four leg alloy chain slings are required to be assembled onto a Master-Sub Link Assembly. This is stated in both OSHA 1910.184 and ASME B30.9. The OSHA FIG. N-184.3 drawing of a quad alloy chain assembly clearly shows a master link with welded sub coupling links. The main master link must to be proof tested to six times the rating of a single leg sling in order to be compliant for use on a triple or quad alloy chain sling. The sub joiner links will then hold one or two sling legs depending on if it is a three or four leg chain sling. The larger master-sub coupling links are recommended to be used to assemble slings with adjuster legs. Mechanical Coupling Links as sub joiner links is not permitted. Placing a single chain leg and shortening leg onto the same mechanical coupling link is also not permitted. Mechanical coupling links are designed for use in a straight line pull and there is no prevision to have a 120 degree included angle on the mechanical coupling link which is a requirement on a welded master sub link.

Size of Crane Hook

The second factor is addressing the fact that the Master Link has to work safely in conjunction with the crane hook. A master link should be at least 1” wider than the width of the bowl of the crane hook. This will provide for proper bearing to bearing connection between the radiused area of the master link and the bowl of the hook. There should be no light between these two points. If there is light as pictured, this can create a shear point on the master resulting in a catastrophic failure. Pre-mature wearing of the crane hook will likely occur which will lead to a costly crane hook replacement.

should be at least 1” wider than the width of the bowl of the crane hook. This will provide for proper bearing to bearing connection between the radiused area of the master link and the bowl of the hook. There should be no light between these two points. If there is light as pictured, this can create a shear point on the master resulting in a catastrophic failure. Pre-mature wearing of the crane hook will likely occur which will lead to a costly crane hook replacement.

Crane Hook Design

If a crane hook has a curved bowl, pre-mature wearing of the crane hook can occur. This is not the case for DIN Style Crane hooks. DIN Style Crane hooks are a special type of master link application. There are no manufacturers that appear to have designed a master link that will result in a true 100% connection between the bowl of the crane hook and the crown of the master link. The bowl is too flat and wide for this to happen when using a master link component with a radius top. (Peerless has a solution to help resolve any issues with DIN Style crane hooks and the ability to have a master link fit correctly. Contact us!)

Master Links are the crowning jewel of all alloy chain slings. They are very tough yet fully capable of performing the task of supporting large loads within their capacity limits. Selecting the proper master link or master-sub assembly is critical when the chain sling manufacturer is assembling a chain sling for any application. Knowing the master link requirements for selection assembly will also make the annual documented chain sling inspection result in a much safer workplace for all.